Junta Acerrojada Doble Cámara Lok&Play®

máxima expresión del desarrollo tecnológico de los sistemas de acerrojamiento

Las uniones con Acerrojamiento de Doble Cámara Lok&Play® (o uniones de bloqueo) son la máxima expresión del desarrollo tecnológico de los sistemas de acerrojamiento.

Garantiza la estanquidad de la unión y conexión de la tubería incluso en situaciones extremas.

Características:

- Deflexión hasta 5º

- Presión de trabajo hasta 100bars (1450psi)

- Fuerza de tracción hasta 10700 KN

- Gama completa de accesorios acerrojados

Funcionamiento

Las tuberías son equipadas con un extremo liso con cordón de bloqueo y una campana en la que el extremo liso es enchufado.

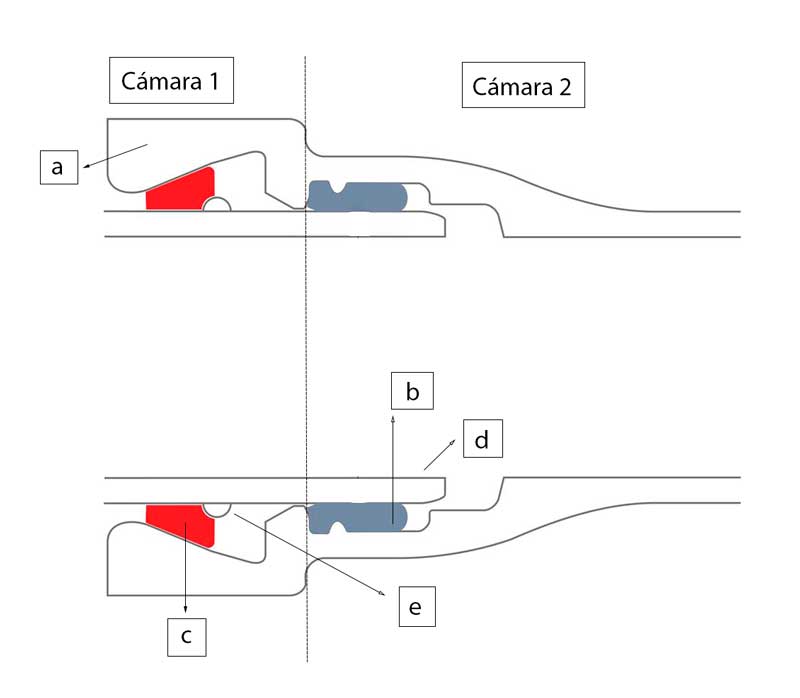

La campana (a) dispone de dos cámaras. En la cámara 1 (la de estanquidad) se aloja la junta TYTON® (b), con la que conseguimos la estanquidad de la unión. La cámara 2 (la de bloqueo) dispone de una ventana (o varias, según diámetro) sobre la que se insertan los segmentos de bloqueo (c) una vez enchufado el extremo liso o espiga del tubo (d), y se deslizan hasta su posición alrededor de la campana. La espiga viene equipada desde fábrica un cordón de bloqueo (e). Realizada la conexión de la unión, se procede a bloquear la unión mediante un traccionado (pull back). Se produce el contacto de a+c+e que proporciona un cierre axial positivo que evita que la ésta pueda desconectarse.

Una vez bloqueada la conexión, la tubería está lista para el funcionamiento, y no se desconecta. Este tipo de acerrojamiento tiene un sencillo montaje, lo que ahorra mano de obra y evita cualquier margen de error, dado que tienen una única posición de introducción y convierte la línea de tubería en autoportante. Permitiendo de este modo, la eliminación o reducción de los bloques de hormigón (concreto) ya que no precisa de anclajes en las uniones, ni siquiera en los codos.

Una vez bloqueada la conexión, la tubería está lista para el funcionamiento, y no se desconecta. Este tipo de acerrojamiento tiene un sencillo montaje, lo que ahorra mano de obra y evita cualquier margen de error, dado que tienen una única posición de introducción y convierte la línea de tubería en autoportante. Permitiendo de este modo, la eliminación o reducción de los bloques de hormigón (concreto) ya que no precisa de anclajes en las uniones, ni siquiera en los codos.